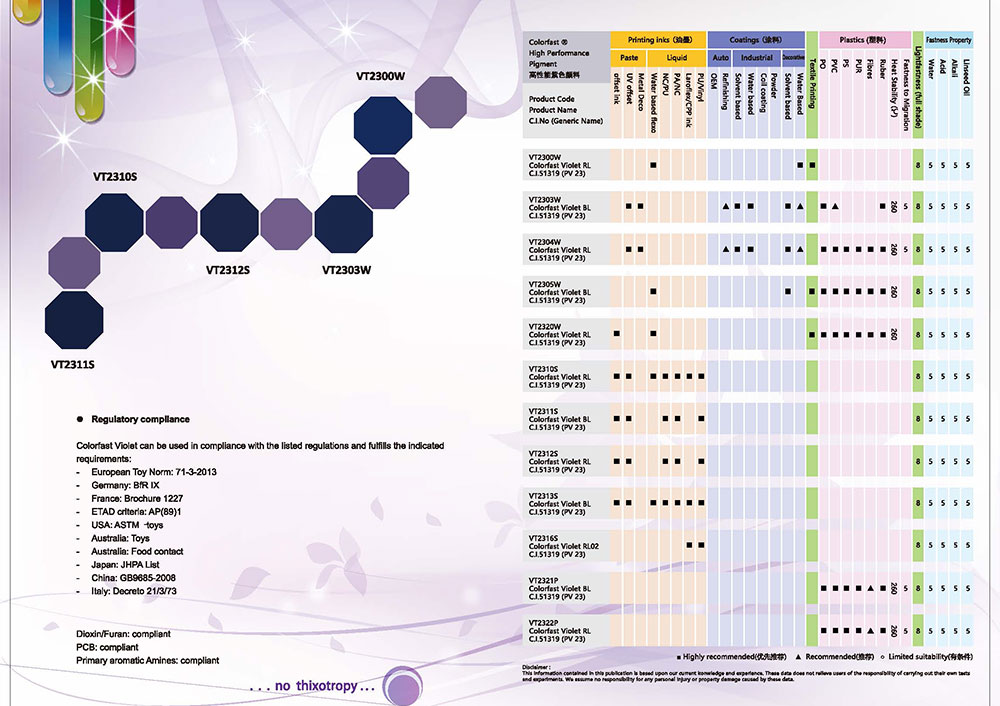

VT2311S/VT2312S For Solvent-based Printing Ink

2017-11-29 1295High viscosity of solvent packaging ink formulated by Pigment Violet 23 is a well known problem and offers one of the biggest challenge to today’s packaging ink formulators particularly in the growing field of “fast printing” (450mps or above).

Most of violet pigments cause significant rheological problems and poor transfer at shallow cylinders. The objective is to maintain a high level of performance throughout the printing process and to ensure that acceptable flow and transfer is maintained through the long print runs. In addition, to reduce the cost of ink manufacture by maximizing production efficiency by way of concentrated ink base.

• The Solution – COLORFAST VT2311S/VT2312S

• High color strength, exceptional high gloss and transparency

• Exceptionally low viscosity & excellent rheological stable

• Highest millbase loadings

• High dispersibility

Excellent steam and boiling resistance

Fully complaint for food packaging

Primarily Used for:

• Solvent based ink concentrates, NC alcohol system/ester/glycol

• Solvent based ink, PU/Vinyl

• Solvent based ink, PA/NC

• UV offset +UV Flexo systems

• Solvent based ink, PVB

• Water based ink, Flexo

- Previous:Full REACH Registration…

- Next:Introducing Violetech – the…